The box part is the basic part of the machine or component. It connects the relevant precision parts into a whole, so that these parts maintain the correct relative position and can work in harmony with each other. Therefore, the manufacturing accuracy of the box part processing will directly affect the machine or The assembly quality of the components affects the performance and life of the machine. Therefore, the box generally has high technical requirements.

2. Technical analysis of gearbox

The main plane of the box is the assembly datum, and it is often the positioning datum during CNC machining, so it should have a high flatness and a small surface roughness value, otherwise it will directly affect the positioning accuracy of the box during machining and affect the box. Contact stiffness and mutual positional accuracy during final assembly with the cover. The dimensional accuracy, shape accuracy and surface roughness of the bearing support hole on the box itself are required to be high, otherwise the matching accuracy of the bearing and the box hole will be affected, the rotation accuracy of the shaft will be reduced, and the transmission parts (such as gears) will be reduced. Vibration and noise are generated.

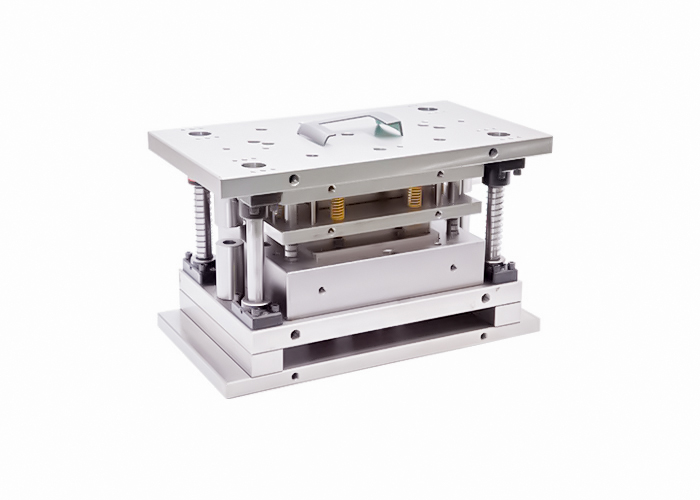

The entire processing process is divided into two major stages. First, the cover and base are precision machined separately, and then the assembled overall box is machined. The first stage mainly completes the processing of planes, fastening holes and positioning empty parts to prepare for the assembly of the box body; the second stage is to process the bearing holes and their end faces on the assembled box body. A fitter process should be arranged between the two stages, the cover and the base should be combined into a box, and positioned with a two-cone pin to maintain a certain positional relationship to ensure the machining accuracy of the bearing hole and the repeatability after removal.

3. Vertical three-axis machining center

This time, the processing of the gear case cover is not difficult for Huiwen. It is enough to use a vertical three-axis machining center to complete the machining. Vertical three-axis machining center, machining table 850mm, machining stroke (mm) X/Y/Z=850/550/550, machining accuracy up to ±0.01mm. Vertical machining center can complete milling, boring, drilling, tapping Threading and cutting threads and other processes. In addition, the workpiece clamping and positioning are convenient, the movement trajectory of the cutting tool is easy to observe, the debugging program is convenient to check and measure, problems can be found in time, and the shutdown processing or modification can be carried out. Consistent with the Cartesian coordinate system, the intuitive feeling is consistent with the pattern viewing angle, the chips are easily removed and dropped, and the processed surface can be prevented from being scratched.

English

English España

España Deutsch

Deutsch